http://scholar.google.com/citations?hl=en&user=95SvbM8AAAAJ

Chipara, A. C.; Tsafack, T.; Owuor, P. S.; Yeon, J.; Junkermeier, C. E.; van Duin, A. C. T.; Bhowmick, S.; Asif, S. A. S.; Radhakrishnan, S.; Park, J. H.; Brunetto, G.; Kaipparettu, B. A.; Galvão, D. S.; Chipara, M.; Lou, J.; Tsang, H. H.; Dubey, M.; Vajtai, R.; Tiwary, C. S.; Ajayan, P. M.

Underwater Adhesive using Solid–liquid Polymer Mixes Journal Article

Em: Materials Today Chemistry, vol. 9, pp. 149-157, 2018.

@article{Chipara2018,

title = {Underwater Adhesive using Solid–liquid Polymer Mixes},

author = {A.C. Chipara and T. Tsafack and P.S. Owuor and J. Yeon and C.E. Junkermeier and A.C.T. van Duin and S. Bhowmick and S.A.S. Asif and S. Radhakrishnan and J.H. Park and G. Brunetto and B.A. Kaipparettu and D.S. Galvão and M. Chipara and J. Lou and H.H. Tsang and M. Dubey and R. Vajtai and C.S. Tiwary and P.M. Ajayan},

url = {https://www.sciencedirect.com/science/article/pii/S2468519418301423#appsec1},

doi = {10.1016/j.mtchem.2018.07.002},

year = {2018},

date = {2018-08-08},

journal = {Materials Today Chemistry},

volume = {9},

pages = {149-157},

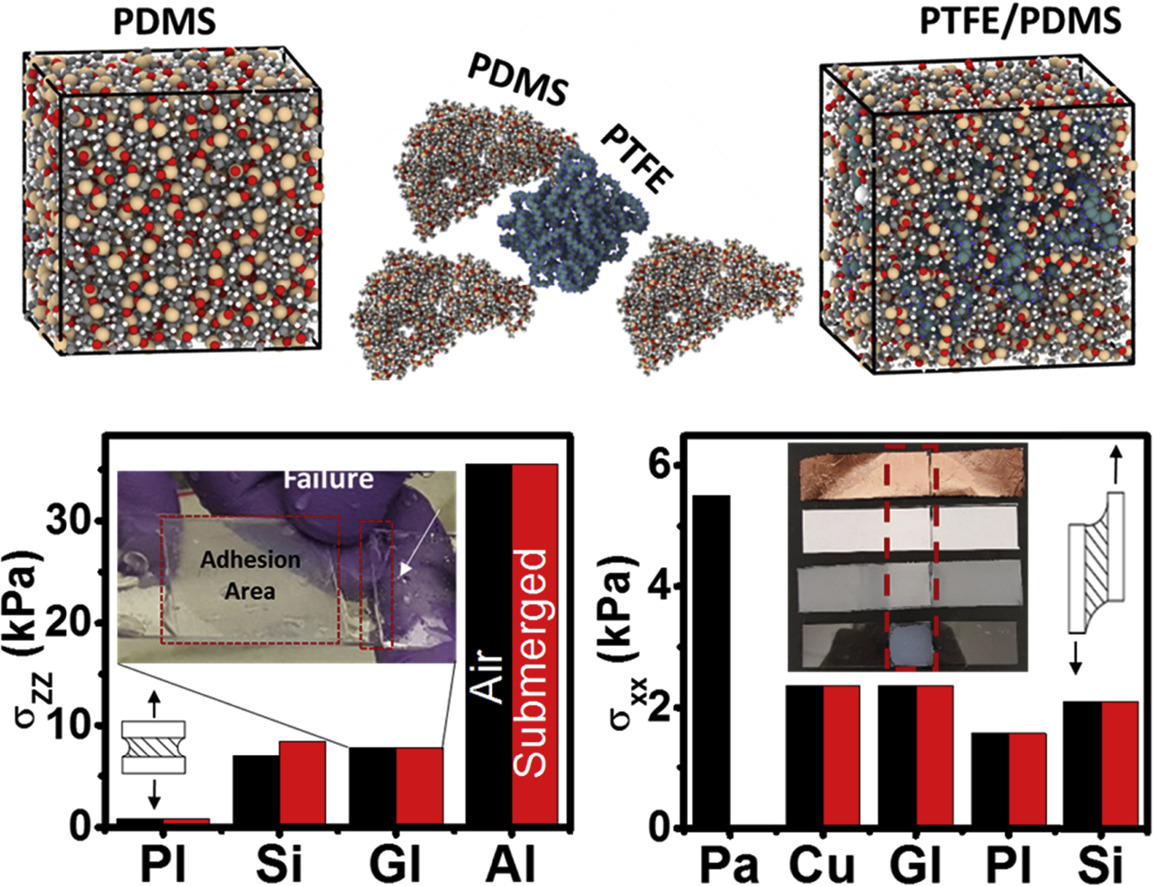

abstract = {Instantaneous adhesion between different materials is a requirement for several applications ranging from electronics to biomedicine. Approaches such as surface patterning, chemical cross-linking, surface modification, and chemical synthesis have been adopted to generate temporary adhesion between various materials and surfaces. Because of the lack of curing times, temporary adhesives are instantaneous, a useful property for specific applications that need quick bonding. However, to this day, temporary adhesives have been mainly demonstrated under dry conditions and do not work well in submerged or humid environments. Furthermore, most rely on chemical bonds resulting from strong interactions with the substrate such as acrylate based. This work demonstrates the synthesis of a universal amphibious adhesive solely by combining solid polytetrafluoroethylene (PTFE) and liquid polydimethylsiloxane (PDMS) polymers. While the dipole-dipole interactions are induced by a large electronegativity difference between fluorine atoms in PTFE and hydrogen atoms in PDMS, strong surface wetting allows the proposed adhesive to fully coat both substrates and PTFE particles, thereby maximizing the interfacial chemistry. The two-phase solid–liquid polymer system displays adhesive characteristics applicable both in air and water, and enables joining of a wide range of similar and dissimilar materials (glasses, metals, ceramics, papers, and biomaterials). The adhesive exhibits excellent mechanical properties for the joints between various surfaces as observed in lap shear testing, T-peel testing, and tensile testing. The proposed biocompatible adhesive can also be reused multiple times in different dry and wet environments. Additionally, we have developed a new reactive force field parameterization and used it in our molecular dynamics simulations to validate the adhesive nature of the mixed polymer system with different surfaces. This simple amphibious adhesive could meet the need for a universal glue that performs well with a number of materials for a wide range of conditions.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

Dong, Pei; Chipara, Alin Cristian; Loya, Phillip; Yang, Yingchao; Ge, Liehui; Lei, Sidong; Li, Bo; Brunetto, Gustavo; Machado, Leonardo Dantas; Hong, Liang; others,

A Solid-liquid Self-adaptive Polymeric Composite Journal Article

Em: ACS Applied Materials & Interfaces, vol. 8, não 3, pp. 2142–2147, 2016.

@article{Dong2016,

title = {A Solid-liquid Self-adaptive Polymeric Composite},

author = {Dong, Pei and Chipara, Alin Cristian and Loya, Phillip and Yang, Yingchao and Ge, Liehui and Lei, Sidong and Li, Bo and Brunetto, Gustavo and Machado, Leonardo Dantas and Hong, Liang and others},

url = {http://pubs.acs.org/doi/abs/10.1021/acsami.5b10667},

doi = {10.1021/acsami.5b10667},

year = {2016},

date = {2016-01-01},

journal = {ACS Applied Materials & Interfaces},

volume = {8},

number = {3},

pages = {2142–2147},

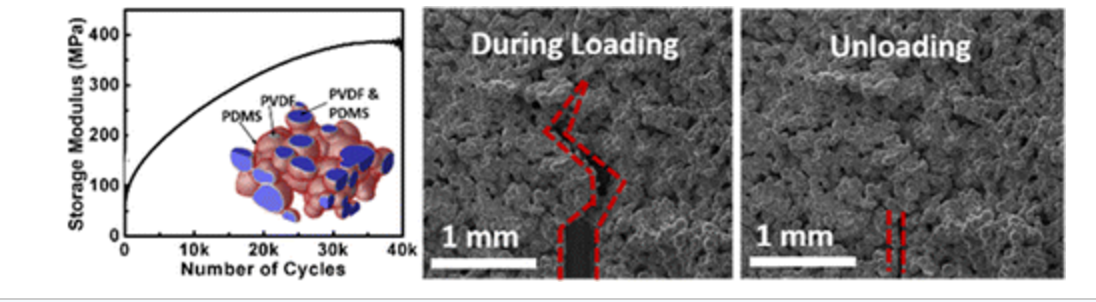

abstract = {A solid–liquid self-adaptive composite (SAC) is synthesized using a simple mixing–evaporation protocol, with poly(dimethylsiloxane) (PDMS) and poly(vinylidene fluoride) (PVDF) as active constituents. SAC exists as a porous solid containing a near equivalent distribution of the solid (PVDF)–liquid (PDMS) phases, with the liquid encapsulated and stabilized within a continuous solid network percolating throughout the structure. The pores, liquid, and solid phases form a complex hierarchical structure, which offers both mechanical robustness and a significant structural adaptability under external forces. SAC exhibits attractive self-healing properties during tension, and demonstrates reversible self-stiffening properties under compression with a maximum of 7-fold increase seen in the storage modulus. In a comparison to existing self-healing and self-stiffening materials, SAC offers distinct advantages in the ease of fabrication, high achievable storage modulus, and reversibility. Such materials could provide a new class of adaptive materials system with multifunctionality, tunability, and scale-up potentials.

},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

2018

Chipara, A. C.; Tsafack, T.; Owuor, P. S.; Yeon, J.; Junkermeier, C. E.; van Duin, A. C. T.; Bhowmick, S.; Asif, S. A. S.; Radhakrishnan, S.; Park, J. H.; Brunetto, G.; Kaipparettu, B. A.; Galvão, D. S.; Chipara, M.; Lou, J.; Tsang, H. H.; Dubey, M.; Vajtai, R.; Tiwary, C. S.; Ajayan, P. M.

Underwater Adhesive using Solid–liquid Polymer Mixes Journal Article

Em: Materials Today Chemistry, vol. 9, pp. 149-157, 2018.

Resumo | Links | BibTeX | Tags: Adhesives, DFT, Molecular Dynamics, Polymer

@article{Chipara2018,

title = {Underwater Adhesive using Solid–liquid Polymer Mixes},

author = {A.C. Chipara and T. Tsafack and P.S. Owuor and J. Yeon and C.E. Junkermeier and A.C.T. van Duin and S. Bhowmick and S.A.S. Asif and S. Radhakrishnan and J.H. Park and G. Brunetto and B.A. Kaipparettu and D.S. Galvão and M. Chipara and J. Lou and H.H. Tsang and M. Dubey and R. Vajtai and C.S. Tiwary and P.M. Ajayan},

url = {https://www.sciencedirect.com/science/article/pii/S2468519418301423#appsec1},

doi = {10.1016/j.mtchem.2018.07.002},

year = {2018},

date = {2018-08-08},

journal = {Materials Today Chemistry},

volume = {9},

pages = {149-157},

abstract = {Instantaneous adhesion between different materials is a requirement for several applications ranging from electronics to biomedicine. Approaches such as surface patterning, chemical cross-linking, surface modification, and chemical synthesis have been adopted to generate temporary adhesion between various materials and surfaces. Because of the lack of curing times, temporary adhesives are instantaneous, a useful property for specific applications that need quick bonding. However, to this day, temporary adhesives have been mainly demonstrated under dry conditions and do not work well in submerged or humid environments. Furthermore, most rely on chemical bonds resulting from strong interactions with the substrate such as acrylate based. This work demonstrates the synthesis of a universal amphibious adhesive solely by combining solid polytetrafluoroethylene (PTFE) and liquid polydimethylsiloxane (PDMS) polymers. While the dipole-dipole interactions are induced by a large electronegativity difference between fluorine atoms in PTFE and hydrogen atoms in PDMS, strong surface wetting allows the proposed adhesive to fully coat both substrates and PTFE particles, thereby maximizing the interfacial chemistry. The two-phase solid–liquid polymer system displays adhesive characteristics applicable both in air and water, and enables joining of a wide range of similar and dissimilar materials (glasses, metals, ceramics, papers, and biomaterials). The adhesive exhibits excellent mechanical properties for the joints between various surfaces as observed in lap shear testing, T-peel testing, and tensile testing. The proposed biocompatible adhesive can also be reused multiple times in different dry and wet environments. Additionally, we have developed a new reactive force field parameterization and used it in our molecular dynamics simulations to validate the adhesive nature of the mixed polymer system with different surfaces. This simple amphibious adhesive could meet the need for a universal glue that performs well with a number of materials for a wide range of conditions.},

keywords = {Adhesives, DFT, Molecular Dynamics, Polymer},

pubstate = {published},

tppubtype = {article}

}

2016

Dong, Pei; Chipara, Alin Cristian; Loya, Phillip; Yang, Yingchao; Ge, Liehui; Lei, Sidong; Li, Bo; Brunetto, Gustavo; Machado, Leonardo Dantas; Hong, Liang; others,

A Solid-liquid Self-adaptive Polymeric Composite Journal Article

Em: ACS Applied Materials & Interfaces, vol. 8, não 3, pp. 2142–2147, 2016.

Resumo | Links | BibTeX | Tags: Adhesives, Modelling, Polymers

@article{Dong2016,

title = {A Solid-liquid Self-adaptive Polymeric Composite},

author = {Dong, Pei and Chipara, Alin Cristian and Loya, Phillip and Yang, Yingchao and Ge, Liehui and Lei, Sidong and Li, Bo and Brunetto, Gustavo and Machado, Leonardo Dantas and Hong, Liang and others},

url = {http://pubs.acs.org/doi/abs/10.1021/acsami.5b10667},

doi = {10.1021/acsami.5b10667},

year = {2016},

date = {2016-01-01},

journal = {ACS Applied Materials & Interfaces},

volume = {8},

number = {3},

pages = {2142–2147},

abstract = {A solid–liquid self-adaptive composite (SAC) is synthesized using a simple mixing–evaporation protocol, with poly(dimethylsiloxane) (PDMS) and poly(vinylidene fluoride) (PVDF) as active constituents. SAC exists as a porous solid containing a near equivalent distribution of the solid (PVDF)–liquid (PDMS) phases, with the liquid encapsulated and stabilized within a continuous solid network percolating throughout the structure. The pores, liquid, and solid phases form a complex hierarchical structure, which offers both mechanical robustness and a significant structural adaptability under external forces. SAC exhibits attractive self-healing properties during tension, and demonstrates reversible self-stiffening properties under compression with a maximum of 7-fold increase seen in the storage modulus. In a comparison to existing self-healing and self-stiffening materials, SAC offers distinct advantages in the ease of fabrication, high achievable storage modulus, and reversibility. Such materials could provide a new class of adaptive materials system with multifunctionality, tunability, and scale-up potentials.

},

keywords = {Adhesives, Modelling, Polymers},

pubstate = {published},

tppubtype = {article}

}